Powder steel S390 MICROCLEAN

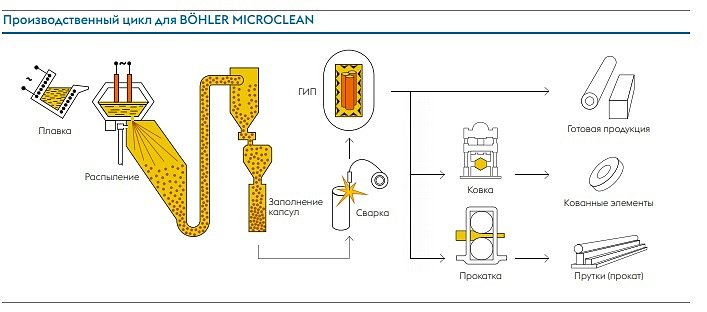

Powder steel S390 MICROCLEAN is a powder metallurgical high-speed steel of the third generation, which is made from exceptionally pure fine powder produced at the modern plant for the production of high-quality powder steels BÖHLER in Kapfenberg, Austria. This alloy is expensive, belongs to the premium class with high hardness and complex mechanical and heat treatment. As a result, its...